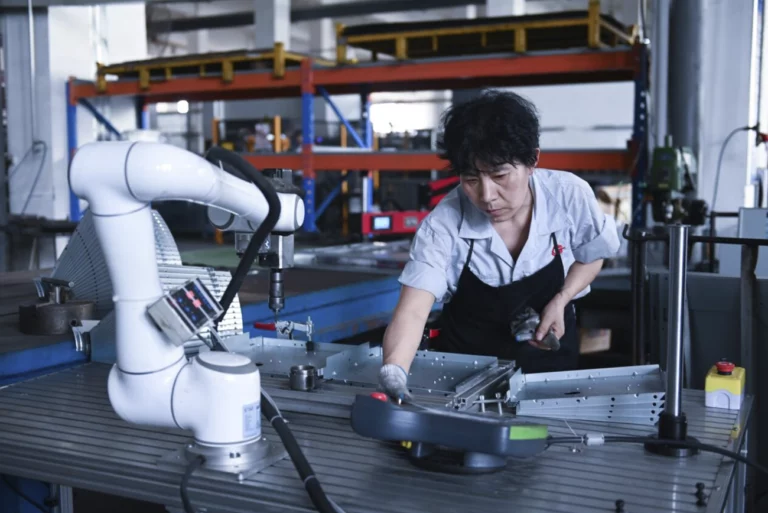

Using Cobot Arms to Automate Production Workflow. Recently, there have been big changes in industrial automation. These changes are mostly due to the use of collaboration robots, or cobots, in production. Cobots are designed to work alongside humans, providing a flexible, safe, and effective option to traditional industrial robots, which are typically kept away from human workers due to safety concerns and complexity.

Understanding Cobot Arms

Cobot arms, also referred to as shared robots, significantly transform the automation process. Designers build these robots to collaborate with people. Cobots are designed to be easily coded and reconfigured, making them highly adaptable to various tasks.

- Each type of cobot has a specific purpose in a production environment.

- Articulated cobots can move like a human arm, making them perfect for tasks that call for dexterity and precision.

- SCARA cobots have a limited range of motion that works well for fast tasks like picking up and placing items.

- Delta Cobots are made to work quickly and easily, and they are often used for sorting and packing.

Depending on the needs of the application, each type has its own benefits, such as speed, reach, and carrying capacity.

Benefits of Integrating Cobot Arms

The efficiency and productivity gains that come from integrating cobots into production processes are substantial. With consistent precision and speed, cobots can operate around the clock and complete repetitive tasks. This nonstop operation reduces downtime and boosts output, both of which are crucial for achieving production goals and enhancing operational efficiency overall.

Flexibility and Adaptability

The flexibility of cobots is much greater than that of standard automation options. It is easy to change their setup for different tasks or to accommodate new product lines. This flexibility is especially helpful in fields where production needs change often, as it lets changes be made quickly without a lot of downtime or retooling.

Cost-Effectiveness

Adding cobots to a business can save a lot of money. The cost may be higher at first than working with your hand, but the long-term benefits usually beat the costs. Cobots cut down on the need for a lot of safety measures, lower the cost of labor, and lessen the costs of mistakes and delays in production. When used in high-volume production settings, the return on investment (ROI) can be very high.

Improved Worker Safety and Ergonomics

Industry safety is important, and cobots make jobs easier. In order to reduce the chance of workplace injuries, cobots are designed to take on hazardous or difficult tasks. Because cobots work together, it is safer for people to deal with them, and they have safety features built in to stop accidents.

Key Considerations for Integration

Examining the current production process and identifying areas where cobots can provide the most value are crucial steps before integrating them. This means looking at the gear that is already there and figuring out how to add cobots without making any changes. To ensure a seamless integration and limit disruptions, compatibility with existing systems and processes is crucial.

Technical and Operational Requirements

For successful integration, it’s important to know how cobots work technically. Payload size, reach, precision, and operational speed are some of the most important variables. It’s also important to think about operational needs, like whether you need special grippers or tools. Matching the cobot’s abilities to the needs of the production process provides the best performance and efficiency.

Training and Skill Development

Before integrating the cobots into a production setting, the staff who will operate and maintain them must receive the necessary training. Investing in training programs helps to ensure that workers are familiar with and proficient at using new technology. Overall output can be raised by coming up with a plan to help workers learn new skills and move into jobs that work well with the new automation.

Steps for Successful Integration

Careful planning and design are the first steps to successful integration. Find out how cobots can be added to the current process by doing a pilot study. Make a detailed project plan that includes picking the right cobot models, planning the layout for integration, and dealing with any problems that might come up.

Implementation

Installing the cobots and getting them ready to work are part of the execution step. This involves verifying the correct setup of all links and settings, as well as integrating the cobots with the existing production systems. During installation, paying close attention to every detail helps prevent problems and ensures that the cobots operate as designed.

Testing and Optimization

Cobots should go through extensive testing after installation to find and fix any problems. To ensure that the cobots complete their tasks correctly and quickly, conduct trial runs. Fine-tuning the system to improve speed and fix any operational problems that come up during testing is what optimization is all about.

Monitoring and Maintenance

To keep cobots working at their best, they need to be constantly inspected and fixed. Establish monitoring systems to monitor performance data and schedule regular maintenance to prevent system failures. The lifespan of the cobots is increased and continuous running is ensured with proactive upkeep.

Conclusion

The chance to increase safety, flexibility, and efficiency in manufacturing settings is significant when cobot arms are integrated into production processes. Companies can successfully use cobots and achieve smooth process automation if they know the benefits, important things to think about, and steps that need to be taken. Cobots will become more and more crucial in determining the direction of production as technology keeps getting better.

If you You should research and consult experts before incorporating cobots into your production processes.n provide good advice. Universal Robotics has the most up-to-date information and stories about the cobot business. Check them out to stay up to date on the latest developments and innovations.